![]()

TYPE 1032 HEAVY DUTY RACK & PINION ACTUATOR

There are several important considerations for evaluating actuator design and its overall performance. Among these considerations are torque output versus cost and size, effectiveness of seals, ease of mounting and adding accessories.

RSVP 1032 actuators are computer designed to properly balance these criteria and to provide the alternative or combination of alternatives that best fit your particular needs. Quality, safety, dependability and efficiency are built into every RSVP 1031 actuator. These actuators are manufactured for RSVP, using state-of-the-art machinery and quality assurance compliying to ISO 9001 and PED 97/23/EC.

1. Two independent external travel stops

permit easy and precise adjustment of plus-or-minus 5° in both directions.

Adjustment screws do not penetrate the pressurized body and eliminates

possible leakage.

2. Modular pre-loaded spring cartridges for safe, efficient use of actuator. Convert a double acting actuator to a spring return actuator by simply removing the end caps and adding from 2-6 spring cartridges on each side to accomplish the desired torque.

3. Hard anodized extruded aluminum body with honed internal surface for strength an lower coefficient of friction. This ensures extended life and low maintenance down-times. The air passages are machined to avoid external tubing. The external shape is contoured and rounded to avoid buildup of contaminents.

4. Compact modular design with same body and end caps for double acting and spring return design.

5. Dual rack and pinion design for compact construction, high cycle life, symmetrical mounting position, fast and efficient operation and offers both spring-to-open and spring-to-close options. Reverse rotation can be accomplished in the field by simply inverting the pistons.

6. All RSVP 1032 actuators are drilled to ISO 5211 standards.

7. Top quality bearings and seals for low friction, high cycle life, to ensure trouble free operation.

8. Stainless steel fasteners and specially coated springs provide corrosion resistance in a variety of environments and applications.

9. The manufacturing of the shaft combines a high strength alloy steel material with a precise machined drive end. The drive is available in parallel square, diagonal square and double "D" output configurations. The guide bar in the piston provides an inherent blowout proof shaft design.

10. Position indicator can be indexed to show alternate position. Top of actuator shaft has a Namur slot to drive all popular sensors and positioners.

11. The design of the stop adjustment cam permits the actuator to be locked out in the full open or full closed position before performing mechanical maintenance work. A special lock out enclosure is available as an option to prevent unwanted operation.

12. Standard end caps are rounded wth no crevices to accumulate contamination or corrosive chemicals. The external and internal surfaces are coated with an epoxy based powder to provide resistance to atmospheric corrosion.

The RSVP 1032 actuator is manufactured in full compliance with the latest requirements of ISO 5211 and EN12116. Provisions for mounting solenoid valves and accessories comply with Namur VDI/VDE 3845.

DIMENSIONS

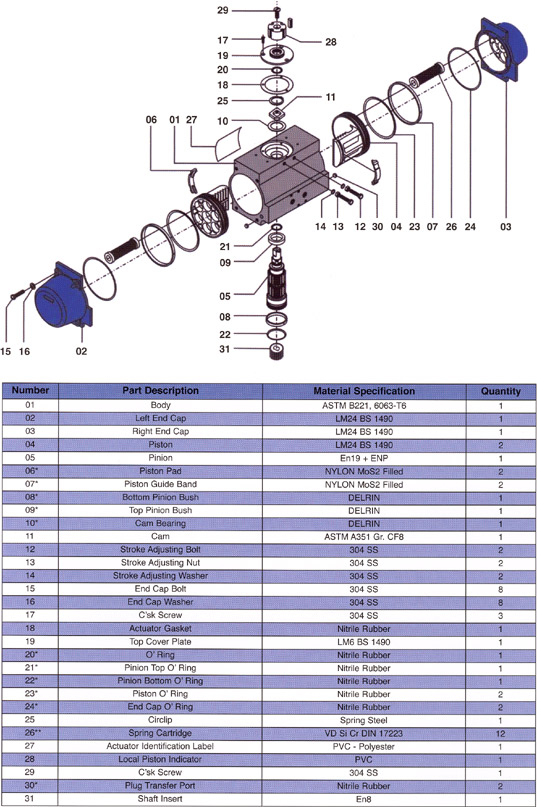

MATERIALS of CONSTRUCTION

OUTPUT TORQUES

HOW to ORDER

RSVP 1032 model numbers are easy to understand.

For example, MODEL NO. 1032 - 160 - 8 - SR - 80 - C1

|

1032

|

Indicates RSVP actuator series |

|

160

|

Indicates size |

|

8

|

Indicates total number of springs |

|

SR

|

Indicates actuator operation |

|

80

|

Indicates spring rating |

|

C

|

Indicates failure mode |

|

1

|

Indicates seal material |