![]()

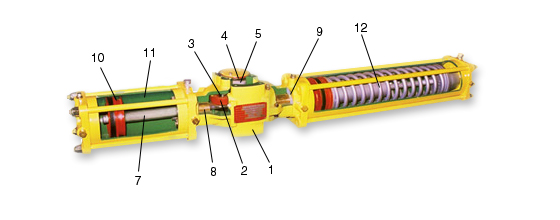

The RSVP 1031 actuator is designed with

three modules. The first module is the center-body. We offer five different

sizes of center-bodies; 26, 33, 45, 60 and 80. The second module is the power

assembly. The third is the spring assembly. The power and spring assembly

modules are removable, serviceable and interchangeable without removing the

center-body module from the valve. This procedure does not require any special

tools.

1. Body Assembly: Heavy duty modular

type body allows every actuator to be made spring return

or double acting.

2. Scotch-Yoke: A balanced scotch-yoke mechanism provides optimum torque

output and maintenance simplicity by transforming

the linear travel of the piston into a 90 degree rotating movement.

3. Thrust Pin & Roller: A

thrust pin is secured to the piston rod and rollers are placed over

the pin to allow free movement within

the slot of the torque plug.

4. Torque Plug Seal: O-rings are located both top and bottom preventing

environments from entering the body housing.

5. Yoke Bearings: Located on both top and bottom of the scotch-yoke,

these UHMW polyethylene replaceable bearings

allow the actuator to cycle more than any actuator in its class

and aid in applications where the actuators are left in one position for years.

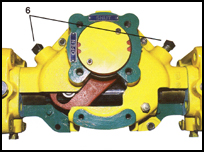

6. Stop Bolts with Jam Nuts: These

bi-directional travel stops are an integral part of the actuator

allowing 80 degree to 100 degree total travel adjustment. Internal travel

stops are optional to prevent tampering.

7. Piston Rod: The piston rod is one continuous steel rod made of 1045

steel bar with a hard chrome plating eliminating

any side load deflections. This design also allows our maximum operating

pressure of 250 psig to apply to all our 1031 actuators.

8. Rod Bearings: These replaceable bronze SAE 660 bearings are secured

between the body and the cylinder adapter, or

rod cover. The bearings are designed to minimize friction.

9. Rod Seals: This dynamic seal between the rod bearings and piston

rod is a molythane

poly-pak seal. The o-rings load the molythane

lips for better low pressure sealing. As the pressure

increases, the lip loading is increased, maintaining an effective seal. There

is also a GarlockTM gasket between the body

and the adapter.

10. Piston: Each piston on all 1031 actuators has the option of having

two piston seals on each piston. This allows

longer life in high cycle applications.

11. Cylinder: The cylinders are finely honed to a very low RMS finish,

and then coated with XYLANTM. This bonds

to the chemically prepared surface of the steel cylinder so effectively that

unlike other coatings, cracking and flaking are virtually eliminated. This

fluoropolymer coating is highly resistant to

abrasion and thermal shock providing excellent lubricity and low friction

properties. Corrosive properties of salts and other chemicals normally

found in the atmosphere or instrument air supply

system will not adversely affect its performance. Stainless

Steel and AmalgonTM cylinders are also available.

12. Spring: Each spring is self-contained and pre-loaded in the cylinder. This

prevents any danger when the actuator is serviced

and allows for field exchange of springs.

Copyright

© 2004 Stockton Company.

All rights reserved.